Three Automation Wins with Practical JDF

Mary Ann Rowan is the Chief Experience Officer for Solimar Systems. She is one of the founders and her team manages the company communications, the Solimar Advisory Council, their global channel partners and events. She is a regular speaker or panelist at conferences. Mary Ann promotes best practices and standards … Read more

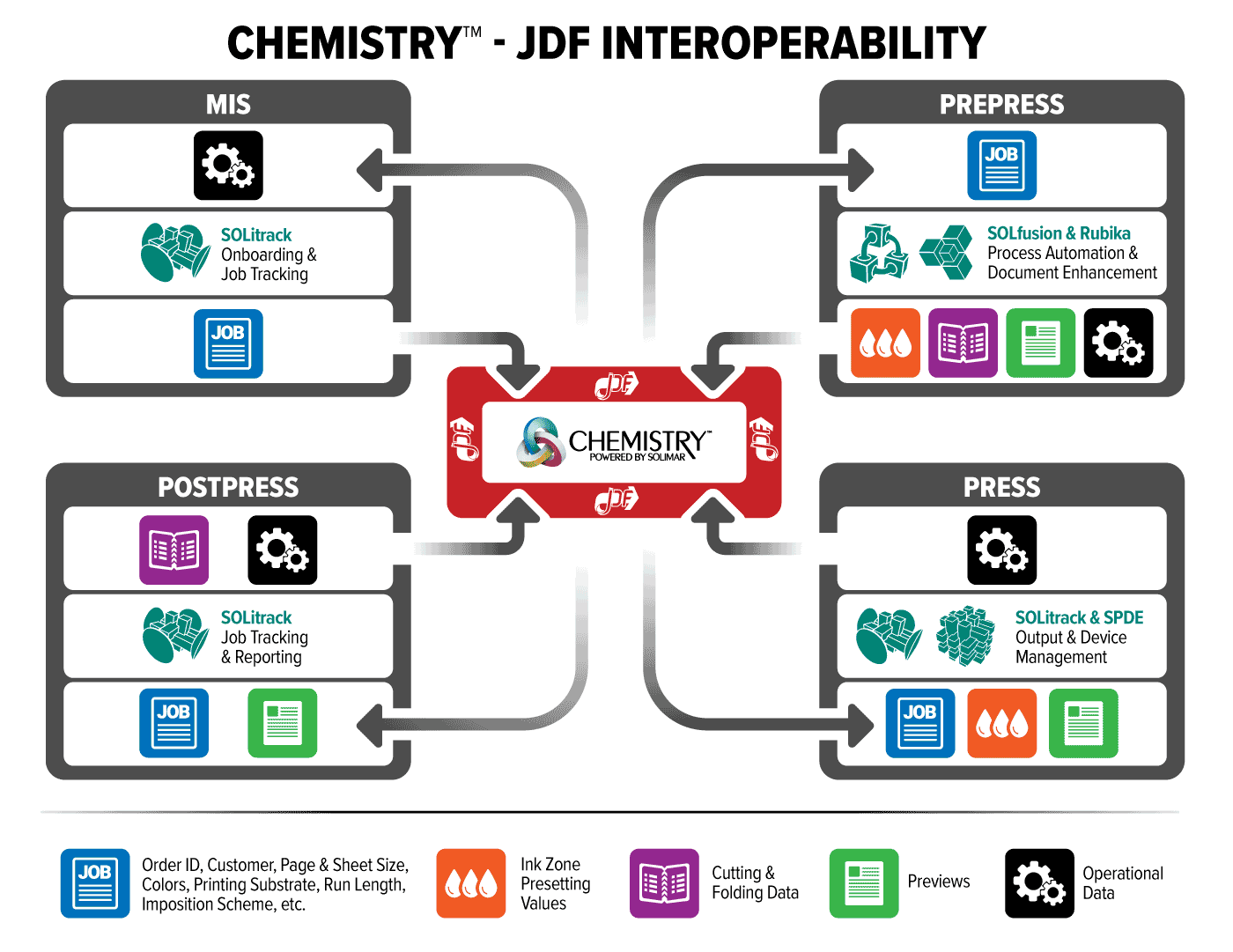

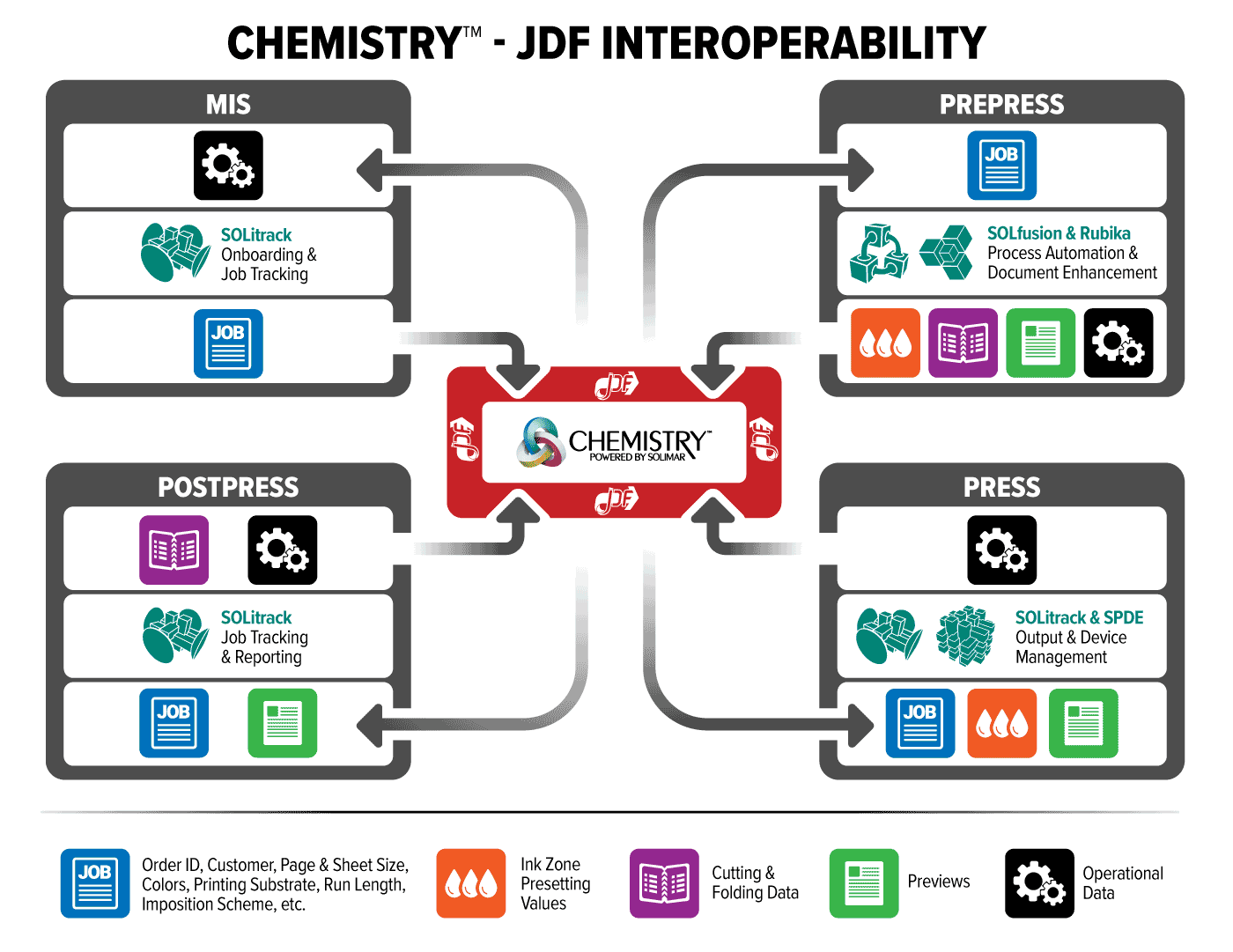

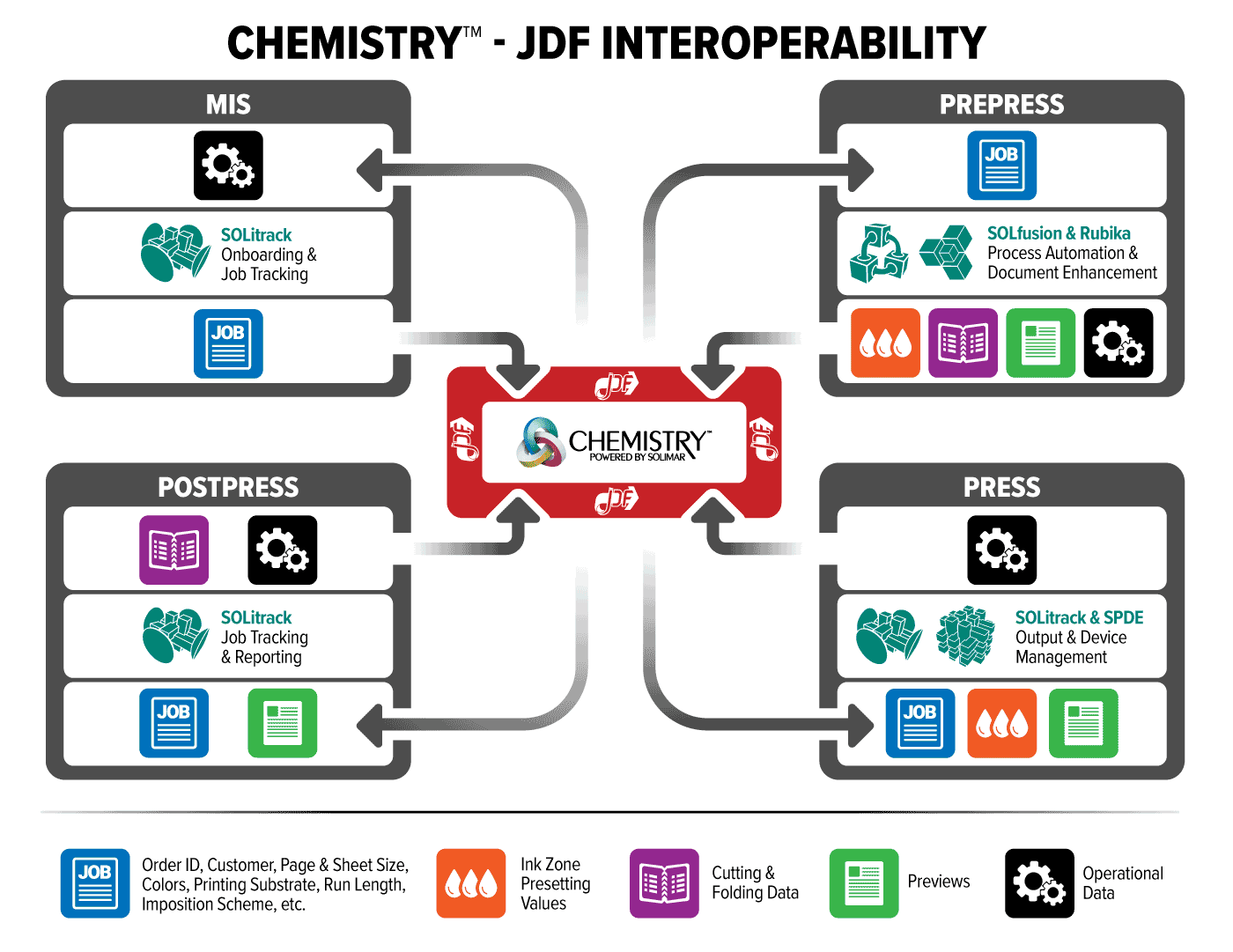

Automation is no longer a buzzword in the printing industry. It is now a necessity to confront industry challenges, from inflationary cost increases to shrinking pools of skilled labor. The textbook definition of automation is “the state of being operated automatically,” which implies the task can be defined, repeated, and executed without intervention. When properly implemented, automation removes touchpoints and their costs while reducing errors in your production print workflow. Solimar uses Job Definition Format (JDF) and Job Messaging Format (JMF) to provide an infrastructure for best-in-class automation!

Automation can be driven physically or digitally. Physical automation drives manufacturing, mechanical systems, and robotics, but software is the powerful, essential element of process automation. As the age of automation dawned in the late 1990s, many industry vendors took part in meetings to develop a standard communication method across the many software tools within the printing industry to enable it.

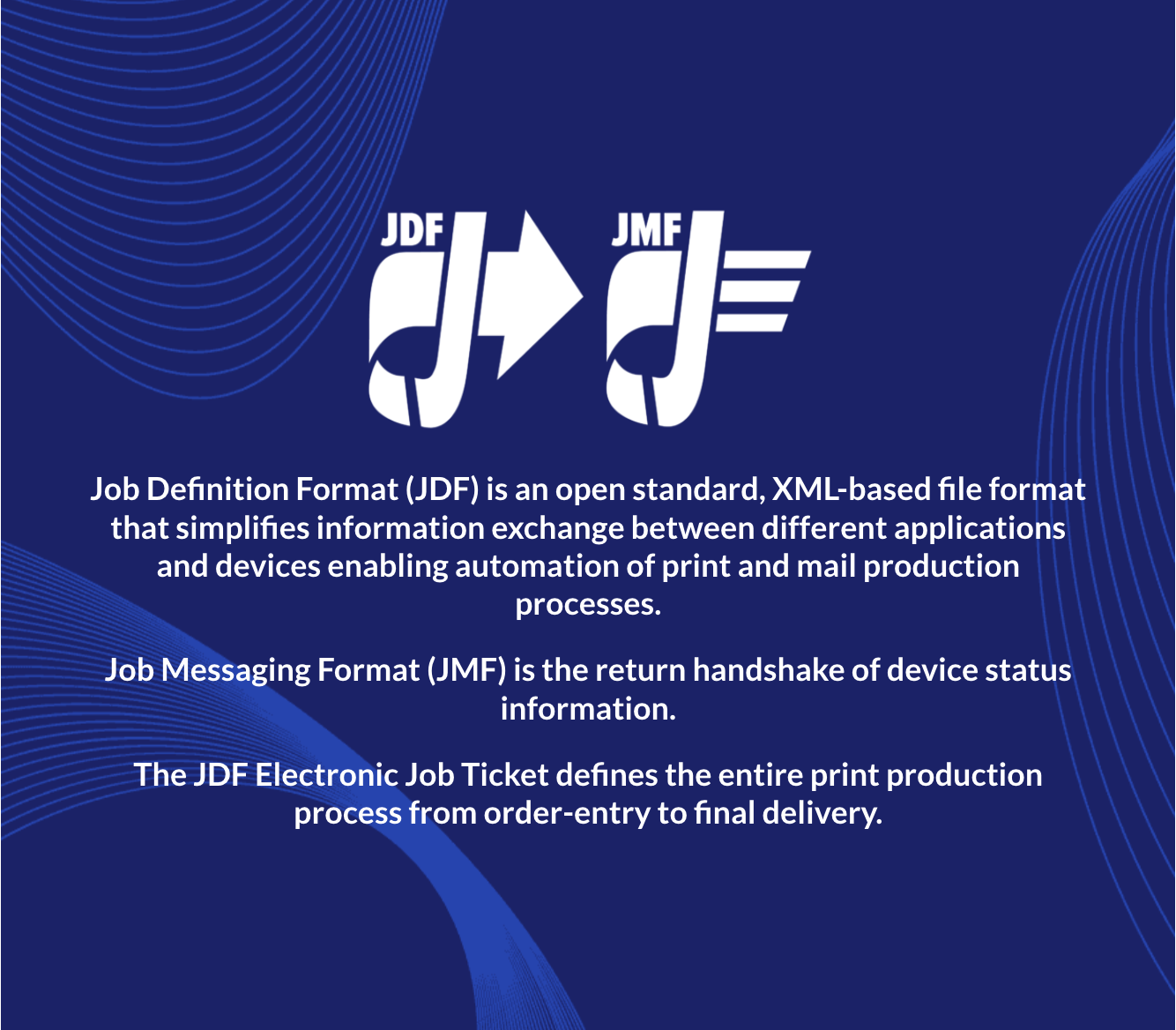

The result was the creation of the Job Definition Format and its companion messaging protocol, Job Messaging Format to enable process automation. A JDF file can contain the definitions for every process required for a print job across every type of printing method using the language of an XML schema. Think of JDF as the set of instructions and JMF as the handshaking that enables processes to share the JDF instructions.

Solimar Solves the Three Top Challenges in Digital Printing with JDF

Offset lithography equipment and software suppliers were early advocates and adopters of the JDF specifications. In recent years, JDF has also become commonplace in digital printing. There are three challenges in digital printing that are well-suited to JDF: page-level finishing, bi-directional communication, and tracking of consumables.

1. Getting the Right Finishing

Page-level finishing includes instructions to automate media settings, tray pull locations, and in-line finishing operations like stapling and folding. The instructions are interpreted by the digital front end (DFE) based on the capabilities of the digital printer. Page-level finishing allows the printer to execute the instructions for each job, bypassing the labor of an operator assigning them through the DFE. Unlike proprietary job tickets, PostScript SetPageDevice commands, or Document Part Metadata (DPM) in a PDF file, JDF is not proprietary and is more widely adopted across print industry vendors. Whether you are working with PDF, PCL, AFP, or PostScript, Solimar's solutions can convert the embedded finishing commands to JDF before sending them to any compatible printer DFE.

2. Controlling Process Communication

JDF/JMF improves bi-directional communication between printers and software systems beyond the capabilities of older protocols like IPP or SNMP. Two-way communication ensures that a job’s status is known. Did the job fail? What percentage of the job is printed? Did the job complete? Were there any errors? These status updates supply transparency to operators and managers so the work can be effectively and efficiently produced. The updates also enable automation through other integrated software solutions like a print MIS. For example, a job completion status could automatically trigger a notification to the client in addition to automatic invoicing.

3. Understanding Consumables

In a mixed-vendor, JDF-enabled printing environment, JDF is a universal format to capture this information from different printing equipment and DFEs. As the print job is being printed, the DFE can collect and update the JDF file with useful data including processing time, alerts, pages processed, ink used and sheets of media consumed. On job completion, Solimar software can then retrieve, store, and report this data to operations staff and management to improve accounting and device utilization.

Process Automation with JDF in Action

JDF can form the foundational infrastructure for complex workflow automation. Many vendors provide easily accessible webhooks, APIs, or other mechanisms to share data using JDF/JMF to create a reliable data exchange network.

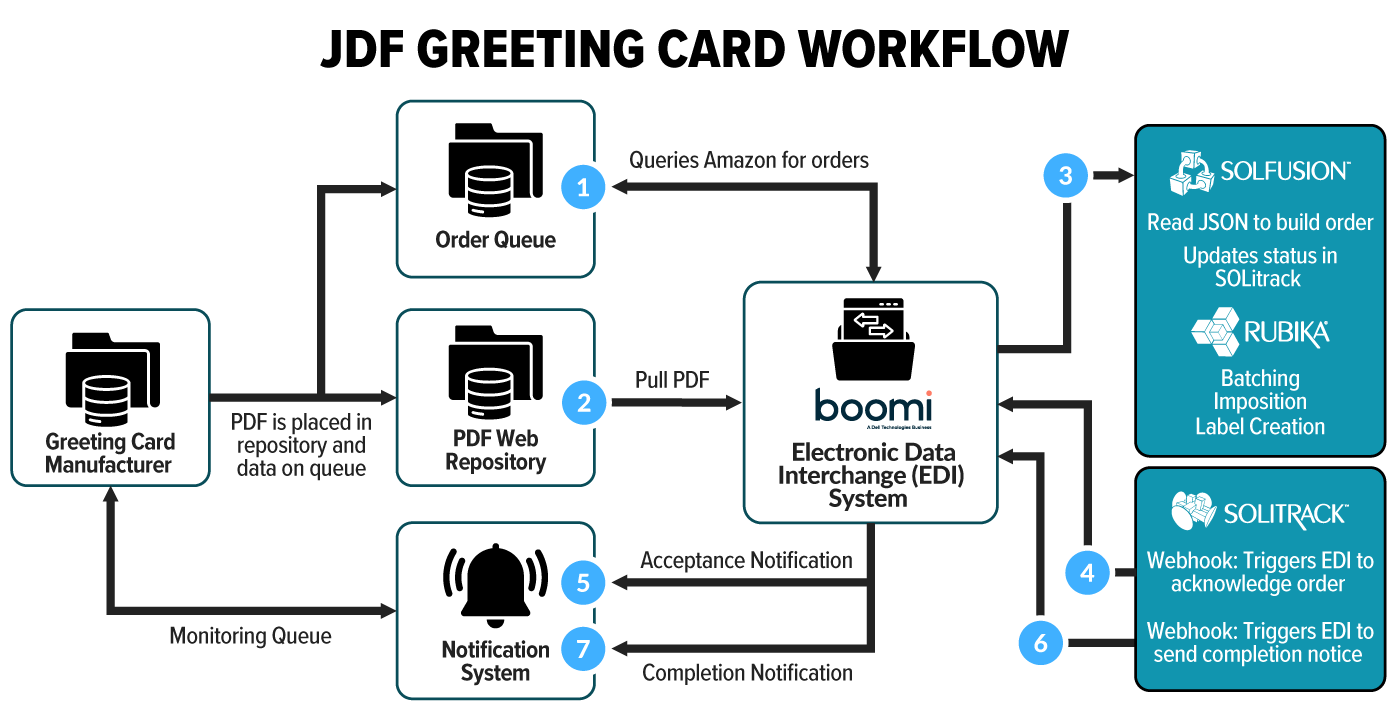

Consider the example of a print manufacturer facing unique challenges due to the volume demands and service-level agreement (SLA) with a major greeting card brand. During peak holiday periods, tens of thousands of greeting cards need to be retrieved, processed, printed, and shipped in a single day. The manufacturer needed to integrate with the brand’s ordering system to retrieve the print order, enable essential status updates, and provide an auditable trail for tracking through print completion and shipping. To complicate matters, gifts are sometimes shipped with the custom greeting cards and managed through the manufacturer’s fulfillment operations.

The manufacturer set up an electronic data interchange (EDI) between the greeting card brand’s ordering system and the online repository for the artwork (PDFs) hosted on Amazon Web Services. Solimar solutions enhance several other points of integration. Solimar SOLfusion processes the JSON files from the EDI system and creates files for order acknowledgment, shipping label creation, and text files to update the EDI when orders are dispatched.

An XML file is created to lodge pick-and-pack orders with the manufacturer’s gift fulfillment software, and the PDF greeting card file is downloaded to print for the greeting card. All PDF files are sent to Solimar’s Rubika for batching and imposition before being sent to the printer. Solimar’s SOLitrack tracks and watches the various processes and production statuses for every job. This includes the JDF provided to automate the digital printers and JMF messages received to update the production status and supply ink and media usage.

The automation provided by Solimar’s workflow allows the greeting card manufacturer to process order volumes that increase year-over-year, including during peak gifting periods. Without the seamless integration between the brand and manufacturer’s systems, the tight turnaround times of the SLA would be virtually impossible. With the automation, consumers receive their gifts and greeting cards on time to the delight of all the partners involved to make it happen.

JDF in practice can be a powerful tool to support automation in your print workflow. Whether it is page-level finishing, improved bi-directional communication, or tracking of consumables used, JDF and JMF keep software, thus staff informed. These three automation wins can make a significant impact in supporting customers and their applications.

Solimar Systems enables organizations around the globe to onboard, make ready, enhance, manage and deliver print and digital communications. As an early adopter of the PDF output format, our Chemistry™ platform optimizes and drives a variety of print and electronic workflows including transactional and direct mail printing, accessibility, archive services,…

Read more